In a highly competitive manufacturing environment, creating systems and processes to help you get the best from every function in your factory or facility is crucial. And this mindset has never been more important when it comes to spend management. In fact, getting the spend approval process right can deliver a whole new level of operational efficiencies, increase visibility, and optimise cost savings.

Everyday spending on resources, raw materials and equipment is part of manufacturing life. Today, we take a look at the spend management approval process because it’s only by understanding that process that you can expect to optimise it. And we’ll see why the right spend approval workflow solution can make life a whole lot easier for everyone in the purchasing cycle.

Your approval process plays a key role

Spend approval is a key element in manufacturing environments but inefficient systems are draining finance teams of precious time and resources. Senior managers are often not happy with the time taken to approve spend. With a reliance on traditional tools like spreadsheets and emails, the lack of visibility and clarity means hours are spent poring over these same spreadsheets and going over-and-back with colleagues. Without one central point to assess who is spending, and what they are spending on, the right approval process can be tricky.

Well designed approval workflows apply a systematic approach to approving spend requests. Your organisation should be able to adjust their purchasing workflow to set clear parameters when it comes to spend on raw materials, equipment or specialist services.

The right workflow means you won’t overspend and everyone will know how much they have spent, and can spend – and all at a glance. Macmarts, has built in key functionality to help you resolve each of these headaches.

The pre-approved spend process

When you purchase from approved suppliers, your manufacturing company is immediately given a degree of confidence in what they are buying. But when you add in extra controls that limit the supply of specific goods from specific suppliers, you are adding another level of spend security.

By setting internal controls and spend policies, you know your team are buying the right products from the best supplier for that product or service. This increases visibility which in turn drives more measured buying behaviour.

Having a spend system that is expansible or can be built on, gives you a solid foundation for the longer term, and offers a systematic approach to spend management. Relying on email and spreadsheets to approve spend is unsustainable and not secure.

How does the approval process work?

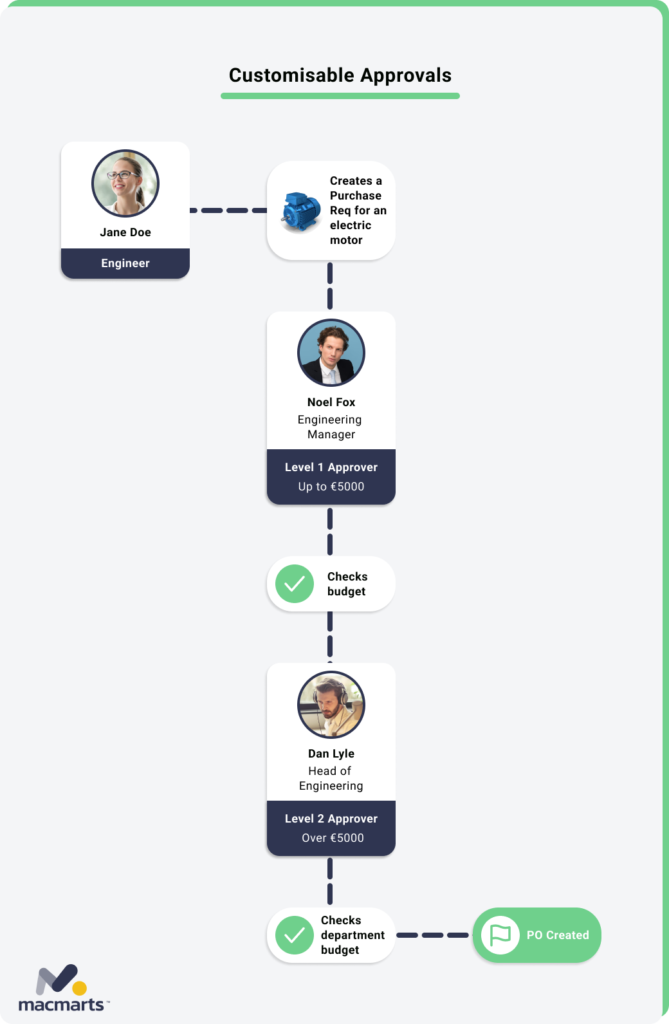

As you can see from our diagram, this spend approval process is one that is ready-made for systematic thinking and prime for automation. At Macmarts, we believe that there are five key considerations when it comes to designing your own spend approval process.

1. Complete your requisition

For manufacturing companies, the spend approval process begins with a request for spend or requisition. Essentially, this is a member of your team signalling that they intend to spend. This provides transparency around what someone needs to buy, and why.

Keep in mind that requisitions are different from Purchase Orders which can strictly only be raised once the request for a PO has been approved. By automating this through Macmarts™, you can convert this tedious administrative process in to a lightning-fast task.

2. Know the chain-of-approval

Before a purchase ever happens, it’s important that you can document and track the approval chain which is simply a record of all the people required to approve a purchase. Let’s say you request to buy new machinery for the factory floor. In this case, the Production Manager will likely need to approve this request before the machinery is purchased. Or if it’s for a significant amount, the Finance Director may well have to approve this request instead.

Documenting and tracking approval chains increases visibility for all people concerned. By being able to see who approved what purchases, transparency is enhanced and visibility is optimised for month-end and other financial reporting needs.

3. Understand permission levels

Naturally enough, smaller purchases require less buy-in from different people. Based on budgets, line or department managers in your manufacturing facility may approve according to what they have to spend – and will also have a localised knowledge of what that spend is for.

More expensive purchases will often have different people making the purchasing decision. These are usually more senior executives but you must also account for situations when people are out sick, on leave, or simply unavailable to sign off on a given purchase. By understanding permission levels in your purchasing approvals process, you can set these automatically with Macmarts™ and ensure a smoother, cleaner process. If you were to handle permission level through spreadsheets or manual processes, purchasing activity will no doubt be subject to huge delays.

4. Set clear timeframes

Scheduling and manufacturing go hand-in-hand and often, certain purchases must be made with specific timeframes or by certain deadlines. In your sector, if a person is requesting to spend, they need to ideally note when the due date or time frame is.

Clear timelines drive transparency and visibility. This also means suppliers know what is expected of them. Macmarts™ allows you set these timeframes, adding another level of visibility to your overall approvals process.

5. Benefit from compliance capability

In the manufacturing sector, checks and balances come with the territory. Executives need to be able to report that they do things the right way, and that they have the documentation to prove it. And purchasing is a fine example of this. Audits are part of everyday commercial life and simply leaving purchasing management in the hands of spreadsheets or emails is a recipe for compliance disaster.

Your approval process demands robust auditing functionality and Macmarts™ can give you one detailed picture on purchasing activity. From requisitions through to purchase orders, Macmarts™ ensures every spend decision will be tracked and documented. This ensures an audit mindset become part of the purchasing approval process.

By adding automation to your spend control workflow through a custom-built solution, you are taking another step forward in digitising your manufacturing company. As the only end-to-end spend control solution developed specifically for life science, manufacturing and engineering companies, Macmarts™ will help you optimise operational efficiency, control spend and maximise visibility.